ROTARflow

Setting the standard of reliable lining operations

The correct amount of sealant is critical to the quality of can ends. How is it controlled now? Once every several hours, samples of lined ends are collected for weight revision. After collecting the weight data, application parameters on liner and injectors are manually readjusted to apply the correct amount of sealant.

Until recently there wasn’t any better way to assure can ends are applied the right quantity of sealant. Now it is different.

ROTARflow is the ultimate solution to control, adjust and monitor the amount of ARTISTICA water-based sealants applied to can ends directly at the point of application, automatically and continuously.

Learn more about the most advanced sealant weight management.

How does the ROTARflow work?

The moment ROTARflow detects a deviation from the established nominal weight of sealant, it modifies application parameters to bring the compound weight back to nominal. The necessary adjustments are performed immediately and automatically.

Compared to a manually controlled lining process, with weight control conducted once in several hours on a small number of samples, the ROTARflow-managed lining process delivers can ends with compound weight that is continuously under control.

ROTARflow is the biggest step forward in can-ends lining operations since the arrival of the electronic injectors.

Head of Technical Service

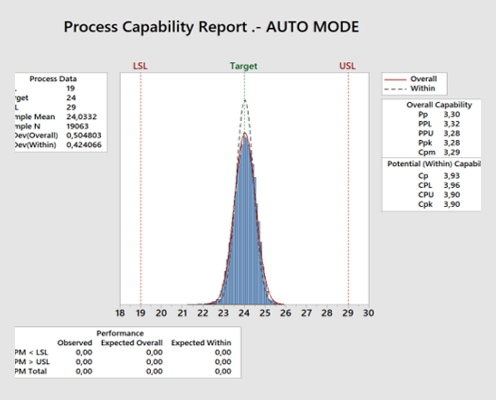

Six-Sigma full process consistency

Process capacity in ROTARflow-controlled application reaches Process Capability (Ppk) of above 2 for full output of ends. In comparison, manual adjustment process can deliver Pp and Ppk values below 1 - for samples of production of ends.

ROTARflow allows the ends makers to achieve a more effective and efficient compound lining process, as it contributes to reduce non-quality cost, and increase reliability of delivered ends in the most demanding seaming processes.

Data-analytics and Digital Services

Digital services include monitorization of sealant film weights and application parameters in real time. Production data, compound weight and application parameters are accessible online.

Full traceability of lining parameters and compound weight to support your process when needed. Access to aggregate data on compound weights and lining parameters with information on production efficiency of lining operations that allow for detailed tracking of performance. Custom Reports to support quality management and decision-making on production capacities, preventive maintenance and much more.

Did you know? It takes about 2 minutes for ROTARflow to perform a compound weight adjustment on up to 10-stations rotary liner at a cold start.

Learn how 2,500 ends per minute can be lined with correct amount of sealant and how to assure lining parameters traceability with ROTARflow technology.