diVar

Beauty lies in the detail

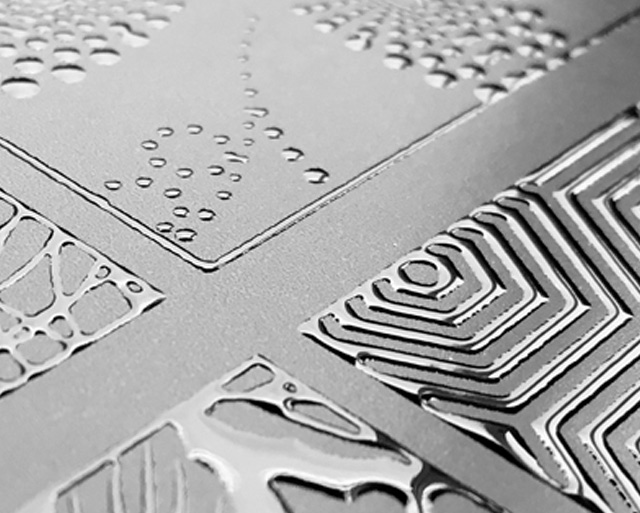

With diVar, our Digital Varnishing technology we have created a new dimension of tactile sensation. Creative visions and exacting standards find their expression in a fascinating and inspiring image rich in detail. We turn visual ideas into sensual reality. Using diVar, various tactile experiences can be achieved in one production run by using different coating depths.

diVar – The idea of digital coating.

This is how it works

Our perception relies on stimuli and uniqueness. diVar will change your way of looking at things. It creates a visual and tactile experience and leaves you with sensory impressions that are immediately perceptible on a wide range of substrates and formats. The technology is virtually limitless in its breadth and can be used to finish paper, cardboard, foil or metal with different effects, at industrial speed and in large formats – for eye-catching, precise and artistic results. Create a new world of surprising images and experiences.

From CTP to CTC (Computer to Coating)

One small step for developers, one giant leap for users! The culmination of digital coating is based on the inkjet technology working in synergy with a new dimension of graphics. The visual concept is projected by the computer directly onto the coating machine and transferred without contact to the substrate. This new dimension of print finishing with tactile effects creates highly distinctive products.

diVar is unique because...

...efficient

Industrial-scale, large-format digital coating means minimum makeready times and maximum productive capacity. Simple operation without press downtimes for makeready operations.

...flexible

No proofs. No advance preparation of templates. Changes and adjustments up to a complete redesign of form and texture can be made directly at the coating machine. With a single coating, you can create a wide range of effects like spot, full-surface or matt/gloss, in a single pass and with varying layer thickness.

...delivers top quality

High-quality effects that create attractive print products are possible even in jobs with very low coating quantities.

...saves resources

Direct coating without prior print form production and with minimum makeready times is one of many benefits offered by the digital technology. Time and cost expenditure is minimal. The cost of print forms, storage, multiple coatings and recycling is eliminated.

...protects the environment

Due to the focused use of substrates and coating, makeready materials are not needed. Waste sheets, cleaning and solvent consumption are minimal.

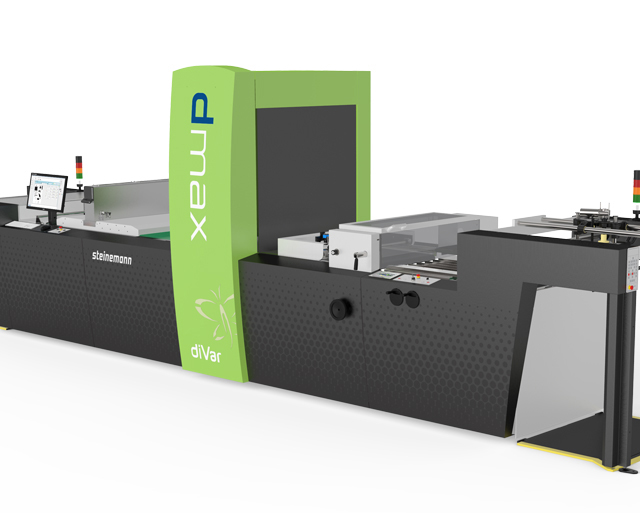

Market-ready solution by Steinemann Technology AG:

You can discover dmax – Digital spot and relief coating for sheet substrates.

Discover our DIVAR adhesives – for digital finishing with or without cold foils