Flexible Packaging

ACTEGA is an international leader in flexible packaging by offering tailored inks, coatings and adhesives.

LEARN MORE

ACTEGA is an international leader in flexible packaging by offering tailored inks, coatings and adhesives.

LEARN MORE

Our focus on innovation is at the heart of our DNA, so we invest heavily in the development of new technologies.

DISCOVER MORE

Our goal is becoming climate-neutral by 2025. Discover more about our commitment to environmental protection.

DISCOVER MORE

Discover our calendar with great images and powerful finishing effects.

MoreYou have already subscribed to our newsletter.

You successfully unsubscribed from our newsletter

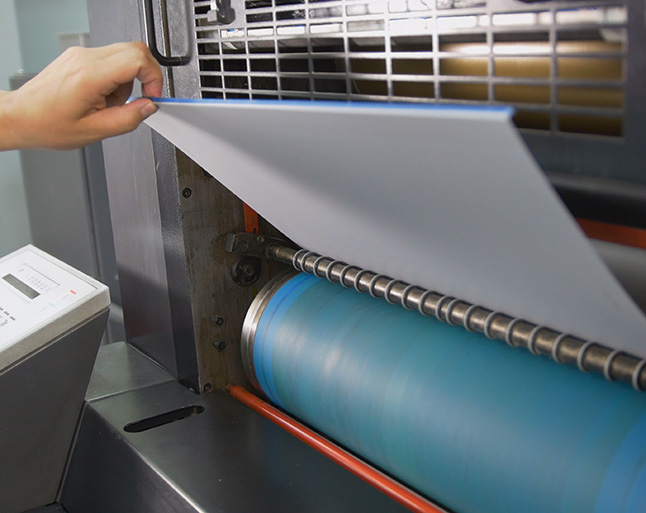

Continue ShoppingInk build-up is a phenomenon that especially appears while using two-roller systems. It develops where printing inks penetrate the coating layer and build up on the rubber blanket or the coating plate. The consequence: The coating application is disturbed. The printing press needs to be stopped and the ink must be removed by means of washing. The result: machine stops and loss of time. In order to prevent ink build-up it is necessary to know the reasons why it may occur.

1. Increase your coating application

If the coating layer is too thin, printing inks can penetrate the coating. Reasons may be a coating application or a coating viscosity which are too low. Viscosity should not be below 30 seconds (DIN 4mm cup).

2. Check your water/ink balance

If too much fountain solution emulsifies into the printing ink, drying is slowed down. The coating can be absorbed, ink build-up is the consequence. Check your fountain solution and adjust it if necessary. Also a pH-value which is too high or a wetting agent add-on which is not suitable for the ink can lead to ink build-up.

3. Reduce your pressure

Too high pressure between counter pressure and impression cylinder or fixed rubber blanket may result in ink build-up. Reduce the pressure in order to prevent that inks are squeezed out at the sides and build up. We recommend the application of a coating blanket. Do not use a rubber blanket out of the ink duct.

4. Choose alternative consumables

If substrate or printing inks are characterized by an insufficient penetration behaviour, the ink can remain on the sheet and build up through the coating layer. Check your consumables and choose – if possible – alternatives with sufficient penetration behavior.

Influence factor: Coating application

Measure: Increase amount, check viscosity

Influence factor: Fountain solution

Measure: Use less fountain solution

Influence factor: Printing press

Measure: Reduce pressure

Influence factor: Substrate

Measure: Apply a substrate with a faster penetration behavior

Still have open questions? Contact us and we will support you with the application.

CONTACT USThe Troubleshooting Series is your source of content with smart tips that helps you to make the most of all ACTEGA products in your processes. In addition to state-of-the-art chemical specialties for the packaging industries, we are your knowledge partner by offering you our technical expertise and useful information.

Discover all of our content