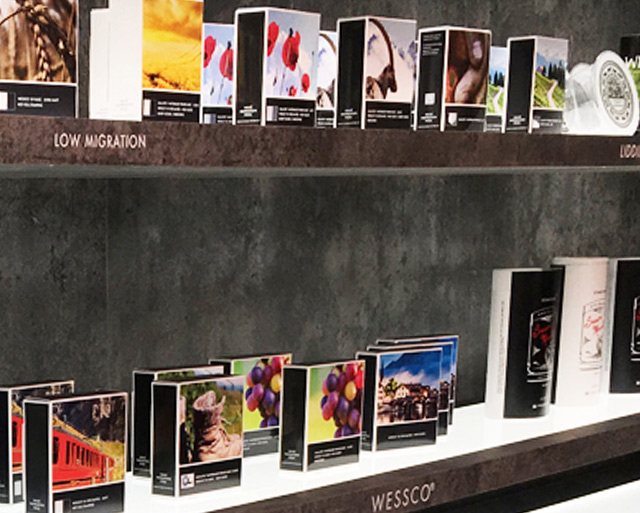

WESSCO® UV Laminating Adhesives

For a Long Life of the Packaging

WESSCO® UV laminating adhesives bond the foil to the substrate and protect the surfaces, making it scuff- and waterproof, as well as resistant to chemicals. The increased tear strength of the paper or cardboard is another great side-effect. The result: a durable print product of excellent quality. Our products are colorless, odorless, solvent-free and therefore eco-friendly. The adhesive composition allows easy processing of pre-treated OPP foils. With the right foil and coating, laminating foils can also be finished with coating effects, turning the product into a tangible highlight.

DIVAR® adhesives – for digital finishing with or without cold foils

For digital finishing with diVar® technology, we have developed a very special adhesive that can be used as a coating in addition to processing cold foils. Our DIVAR® adhesive is applied with a silicone calender and, once it has been cured with UV rays, can no longer be distinguished from a coating. This creates exciting effects which cast a new light on the end product. The advantages of digital printing with digital finishing can therefore be exploited to the fullest.

Our DIVAR® adhesives are available as thin-layer adhesives for quantities of approx. 4 to 32 g/m2 (cold-foil application) and as relief adhesives for quantities of approx. 16 to 64 g/m2 (coating application).

The DMAX machine for digital spot and relief coatings is available for the efficient processing of our DIVAR® coatings/adhesives. This machine was developed together with Steinemann Technology AG and enables the simultaneous application of coatings and adhesives. This saves time by processing in only one pass.

Applications

- Laminating foils

- Aluminum stamping foils

- Stamping foils for coating

- Hologram stamping foils

- Metal stamping foils

- Cold-foil application

- Digital cold-foil application

Advantages

- Saves time

- Work efficiency

- Solvent-free and therefore eco-friendly

- Simple processing

- DIVAR® for cold-foil and coating application in one pass with the same product