Flexible Packaging

ACTEGA is an international leader in flexible packaging by offering tailored inks, coatings and adhesives.

LEARN MORE

ACTEGA is an international leader in flexible packaging by offering tailored inks, coatings and adhesives.

LEARN MORE

Our focus on innovation is at the heart of our DNA, so we invest heavily in the development of new technologies.

DISCOVER MORE

Our goal is becoming climate-neutral by 2025. Discover more about our commitment to environmental protection.

DISCOVER MORE

Discover our calendar with great images and powerful finishing effects.

MoreYou have already subscribed to our newsletter.

You successfully unsubscribed from our newsletter

Continue Shopping

Everybody knows the challenges during the sheet-fed offset printing process: from the basics to the most complex. With detailed explanations and step-by-step guides, we inform you about sources of error, their reasons and support your solution.

Browse popular topics and resources.

Troubleshooting

This refers to a coating layer characterized by a surface similar to an orange peel (running disturbances).

Troubleshooting

Uncoated substrates absorb more moisture and hence are more prone to curling.

Troubleshooting

A phenomenon that especially appears while using two-roller systems.

Troubleshooting

This is the breaking of the substrate‘s outer layers during folding.

Troubleshooting

The more even the surface, the stronger the reflection and the higher the gloss.

Troubleshooting

The matter the coating, the higher the danger of texture in the matt coating.

Troubleshooting

Only if the coating has been properly adjusted, a problem-free application out of the coating unit can be provided.

Troubleshooting

If properly processed, inks and coatings provide good resistance.

Troubleshooting

Different factors can have an influence on adhesion.

Troubleshooting

Cracks in the coating layer (cracking) result from tension.

Troublshooting

Odour and taste are subjective experiences. However, they can have a great influence on the quality of printed products.

Troubleshooting

The blocking of printed sheets in the pile is a result of insufficient drying of inks or coating.

Troubleshooting

Insufficient curing of UV coatings can influence the quality of your printed product.

Troubleshooting

The drying behaviour plays a major role in printing and further processing.

Troubleshooting

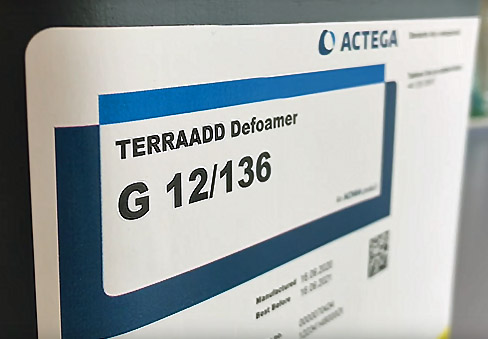

Foam is the result of air distribution in the coating and can cause various problems.